Latest News: On July 7, the signing ceremony of strategic cooperation between Anhui Fengyuan Biofiber Co., Ltd. and Fujian Xintongxing Textile Co., Ltd. was held in Bengbu City.

According to the content of the agreement, Anhui Fengyuan Bio-Fiber Co., Ltd. and Fujian Xintongxing Textile Co., Ltd. will jointly develop polylactic acid environmental protection technology fabrics in the spirit of reciprocity, mutual benefit, stability, long-term, efficient and high-quality cooperation, and give full play to their respective advantages. , establish a comprehensive and multi-level strategic cooperation mechanism. This strategic cooperation promotes the further improvement and upgrading of the business of both parties and achieves coordinated development. It is also based on promoting the development of China's school uniform industry, adding "high-tech elements" to Chinese school uniforms, and students wearing degradable, environmentally friendly and comfortable school uniforms, more healthy More style.

Polylactic Acid (Polylactic Acid) PLA, also known as polylactide, is made from starch-rich crops (corn, potato, sweet potato, wheat, sugar beet, etc.), or straw cellulose as raw material, and is produced by modern biological fermentation technology. It is a kind of polymer material obtained by a special polymerization reaction of small molecule lactic acid, which is a fully bio-based degradable material.

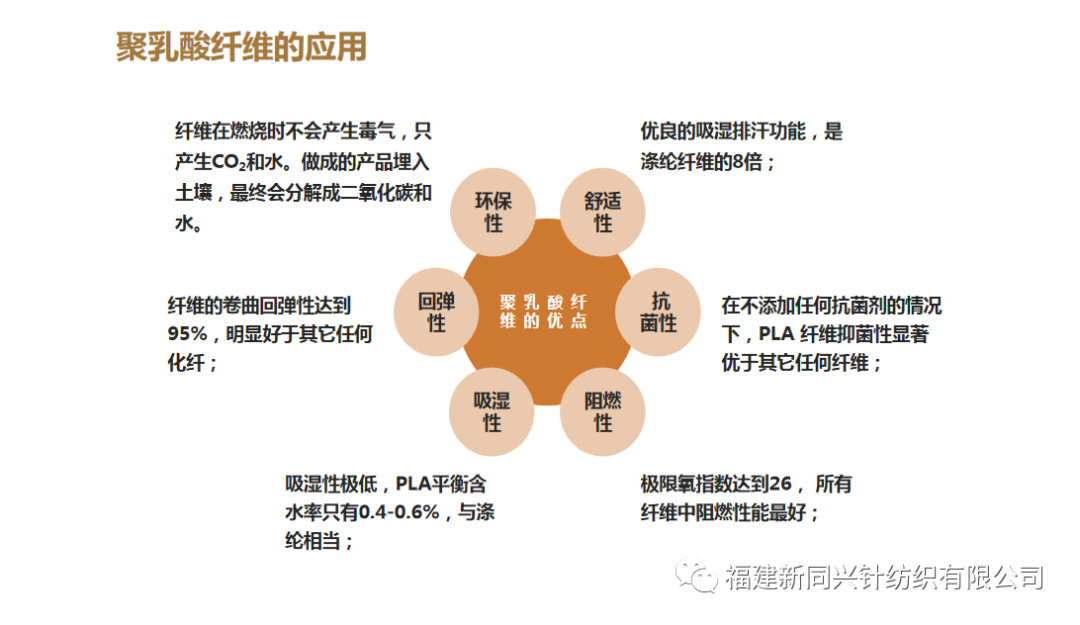

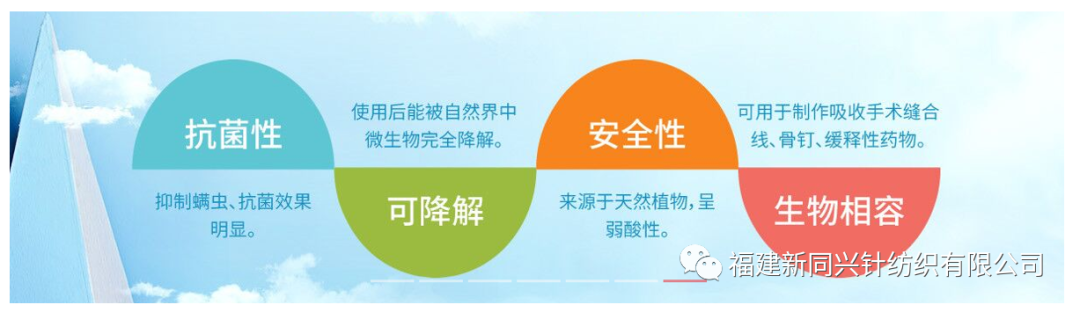

Biofibers and bioplastics made of polylactic acid have many characteristics: it does not contain bisphenol A and formaldehyde, and will not release toxic gases such as nitrogen compounds and sulfides when incinerated; under composting conditions, it can be affected by microorganisms within half a year. Degraded into carbon dioxide and water, and easier to recover and recycle. Secondly, it has good performance and will be widely used in the future. Not only can it be used in the manufacture of various injection molding, sheet and film bag products, but also in the manufacture of textiles, clothing, curtains and other textiles. These products are skin-friendly and moisture-proof, as well as antibacterial, anti-mite, anti-allergic, flame-retardant and fire-resistant. The data shows that the carbon emission of bio-based materials represented by polylactic acid in the whole life cycle is 80%~90% lower than that of petroleum-based materials, which helps to achieve carbon peaking and carbon neutrality goals.

When PLA fiber is applied to student clothing fabric, its excellent moisture absorption and perspiration function is 8 times that of ordinary polyester fiber. Without adding any antibacterial agent, the antibacterial property of PLA fiber is obviously better than that of any other fiber, and the The curling resilience reaches 95%, which is obviously better than any other chemical fiber. Different from ordinary "cotton" products, the fabric made of polylactic acid fiber is skin-friendly, moisture-proof, warm and breathable, antibacterial, anti-mite, anti-allergic, has no special smell, and is flame retardant and fireproof. Children wearing school uniforms made of this fabric are more environmentally friendly, safer and more comfortable.

Fujian Xintongxing Textile Co., Ltd. will continue to focus on students, do a good job in fabric research and development with a more responsible and serious attitude, and develop more innovative products suitable for the school uniform market, hoping to provide children with high-quality products and services. Healthy body , a positive attitude, so that every student can confidently participate in a broader and better future, this is the responsibility and dream of Xintongxing.