| In stock: | Yes | Reaction Components: | Isocyanate-based polyurethane adhesive |

| Type: | Water-based Adhesive | Purpose: | Adhesives for Food Packaging |

| Model: | Xh-fw401 | Specifications: | 20kg |

| Trademark: | Starlight | Packaging: | Iron Bucket |

| Yield: | 1000000 |

Detailed introduction of "water-based dry compound adhesive two-component polyurethane dry compound adhesive light packaging glue"

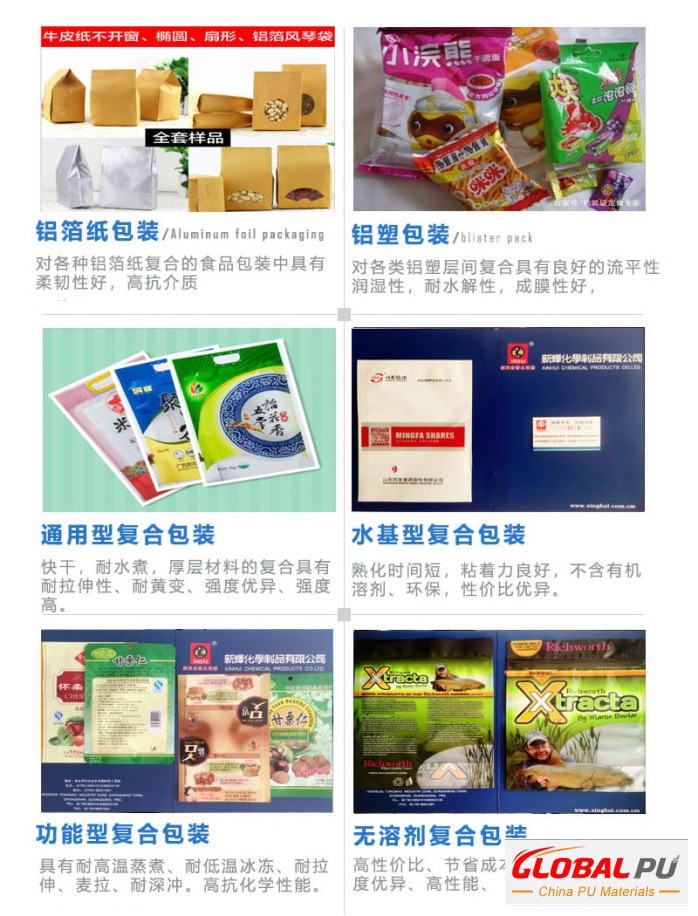

Product application: FW401//FK-100 is a high-performance water-based, cost-effective two-component reactive polyurethane dry compound adhesive, suitable for lightweight packaging Composite materials OPP, CPP, PE, PET, NY, VMPET, VMCPP and other substrates are compounded.

1. This product does not contain free TDI components, does not contain organic solvents, and is a healthy and environmentally friendly adhesive developed by the country.

2. It has good adhesion to various film substrates, high transparency and good leveling, and meets the requirements of light packaging;

3. It is suitable for the compounding of flexible packaging materials with high transparency;

4. Has good leveling and wetting properties, suitable for medium-speed coating.

Three, Technical Specifications:

| Model | Main agent: FW401 |

hardener: FK-100 |

| Appearance |

colorless or light yellow transparent viscous liquid |

colorless or light yellow transparent viscous liquid |

| Solid Content (%) |

40±2 |

98-100 |

| Solvent |

Water |

------- |

| Viscosity (25℃) |

1000~4000 |

1000-5000 |

Four.Reference ratio:

Generally FW401/FK-100=100/5- 15. The ratio is preferably 100/10, and customers can adjust the ratio according to the actual situation for different substrates.

V.Dilution solvent and requirements:

First add water to the main agent, stir well, then add curing agent, and stir well.

6. Working concentration: Generally, the concentration is 20-25%.

7. Application range: General dry lamination

8. Coating weight: 1.5-3.0g/m2 (dry basis), (depending on the film Structure post-processing, use, quality requirements are different)

Compound drying tunnel temperature: must pay attention to have enough air volume, air speed and temperature, the temperature can be selected between 55 ℃ to 95 ℃ . When the drying system is divided into three sections, the temperature from the membrane inlet to the outlet is controlled between 55-75°C, 65-85°C, and 75-95°C.

IX.Aging temperature:50±5℃

TEN.Aging time:24- 48 hours.

TenI.Packaging: Main agent: 20kg/barrel Curing agent: 2kg (can be packaged according to user requirements)< br> TenTwoStorage: Water-based products should be sealed and stored at 20℃ with a lid, in a dry environment, and avoid being placed in the open air; storage and transportation It needs to be insulated, moisture-proof and freeze-proof, and the sealed storage period is half a year.

Thirteen.Notes:

1. Composite substrates such as PE, CPP, BOPP, PET, PA and other films require surface treatment , Its surface tension: PE, BOPP, CPP should reach more than 38 dynes, PET should reach more than 50 dynes, and PA should reach more than 52 dynes.

2. The type and content of film additives have an impact on the bonding strength of the composite film, which should be selected before use. In particular, the content of slip agent in the film is very important and must be strictly controlled.

3.The substrate to be bonded should be clean and dry, free of dust and oil, and must be corona treated, the surface tension Not less than 38 dynes.

4. The type of film additives, glue concentration, the depth of the anilox roll, and the number of lines have an impact on the bonding strength of the composite film, which should be selected before use.

5. In the process of compounding, it is necessary to pay attention to checking and controlling the viscosity of the adhesive; there must be enough coating amount and sufficient curing.

6.After opening the package, it must be used up within a short period of time. Do not mix this product with other adhesives.

7. The formulated adhesiveshould be used up within 8 hours as much as possible, such as whenit is found that the viscosity of the adhesive is obviously increased or appears turbid , should be discontinued.

·

·

Contact Us