"TPSIV non-yellowing silicone vulcanized rubber elastomer" parameter description

| In stock: | Yes | Authentication: | American Standard |

| Type: | Other | Grade: | Non-yellowing silicone |

| Processing Level: | Hollow grade | Usage Level: | Tube Grade |

| Model: | Non-yellowing silicone | Specifications: | 25KG |

| Trademark: | American Standard | Packaging: | American Standard |

"TPSIV Non-yellowing Silicone Vulcanized Rubber Elastomer" Details

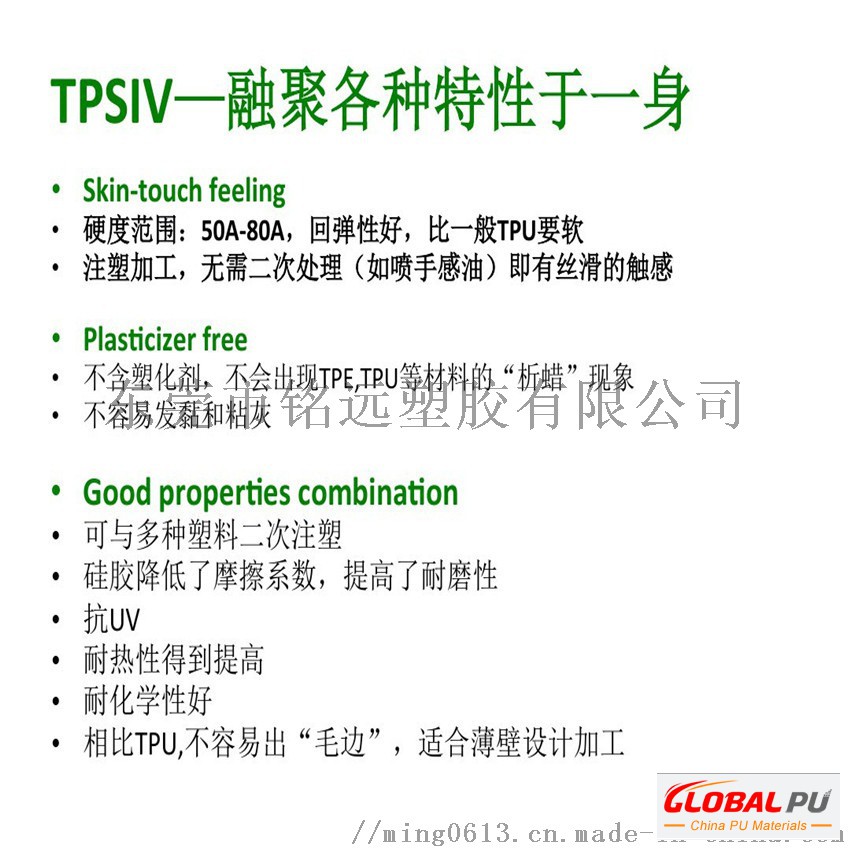

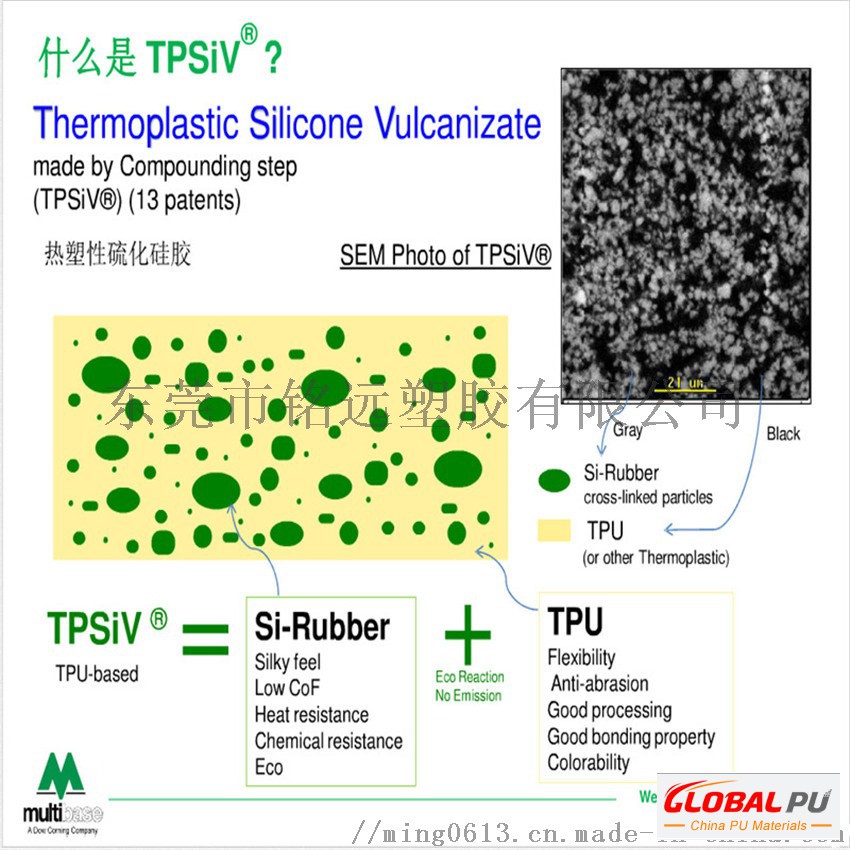

TPSiV is a thermoplastic silicone elastomer (silicone rubber) Properties:

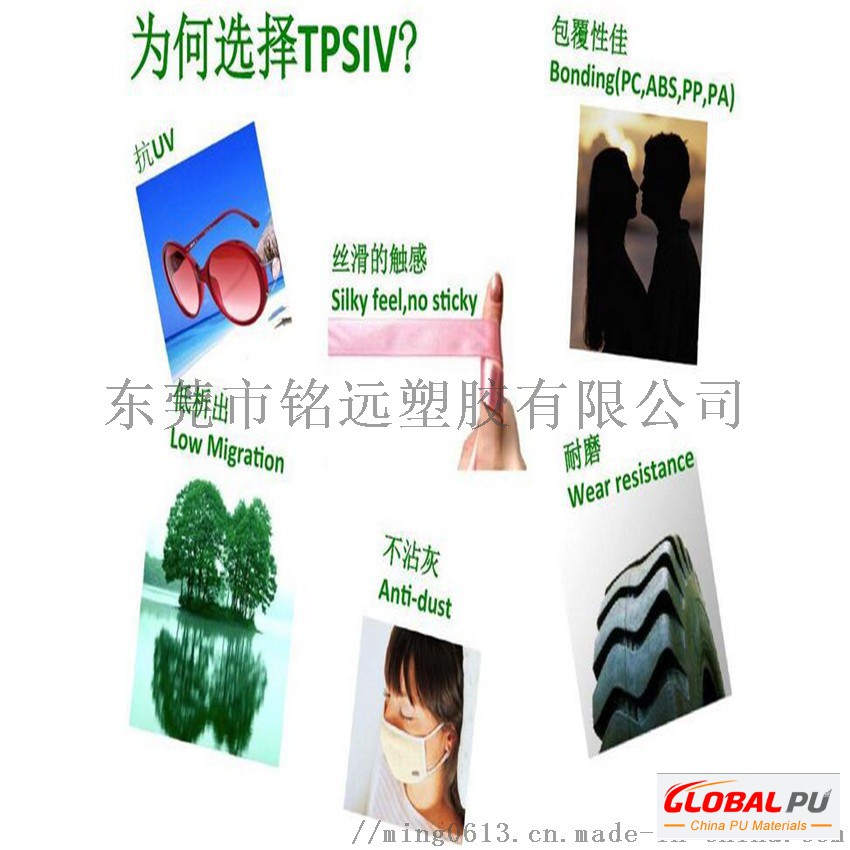

(1) The formula does not contain additives such as solvent oil and plasticizers that can easily cause yellowing, and can be dyed in various colors according to needs;

strong>(2) The surface is not easy to absorb dust; it has good oil and chemical resistance, and is not easy to be polluted;

(3) With many thermoplastic engineering plastics such as PC, PC/ABS. ABS, PA. PVC, etc. have excellent adhesion and can be used for co-extrusion and two-color injection molding;

(4) High mechanical strength can still be maintained after 150℃ hot air or 150℃ high temperature aging; it can be used for silk screen printing, pad printing, and secondary painting processing.

Performance and Features:

TPU matrix: TPU matrix TPSiV combines the respective performance advantages of TPU and silicone materials, with excellent wear resistance, silky touch feeling, The surface friction coefficient is lower than that of TPU, and it has excellent adhesion with PC, PC/ABS, ABS, etc. After hot air aging, it can maintain high physical and mechanical properties, and is easy to extrude and injection molding.

Polyolefin matrix: Polyolefin matrix TPSiV products have good flexibility, low temperature resistance and UV stability, excellent physical and mechanical properties, good PP coating, easy to dye and recycle. Among them, 5520 series products have excellent low temperature performance, and the elongation at break at -40℃ can reach 450%; 5300 series products have a silky touch, suitable for extrusion and injection molding, and are widely used in daily consumer goods, cosmetics, drinking Water lead products hose, sports equipment, etc. Anti-biological bacteria, magnesium, aluminum and other metals wrapped, light engraving.