"TPE antistatic material TPR elastomer material TPE conductive material" parameter description

| In stock: | Yes | Authentication: | American Standard |

| Type: | TPE | Grade: | TPE conductive material |

| Processing Level: | Injection Grade, Extrusion Grade | Feature Level: | High temperature and low temperature resistance |

| Usage Level: | Automobile parts, electrical and electronic parts | Model: | TPE conductive material |

| Specifications: | 25KG | Trademark: | American Standard |

| Packaging: | American Standard |

Detailed introduction of "TPE antistatic material TPR elastomer material TPE conductive material"

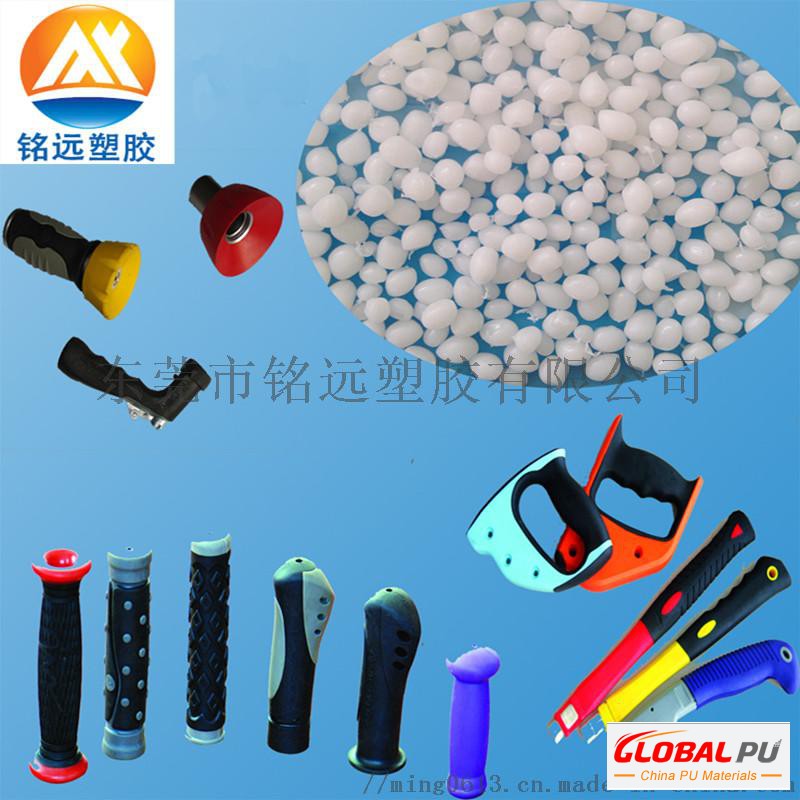

Thermoplastic Elastomer TPR, Also known as thermoplastic rubber, English name Thermo-Plastic Rubber. Appearance is transparent, solid color particles, with rubber characteristics. TPR is a material that has the properties of vulcanized rubber while being thermoplastic. It has excellent resilience, soft touch, abrasion resistance and aging resistance. TPR is a blended modified elastomer alloy based on SBS, SEBSthermoplastic elastomer, its physical properties and hardness (0~100A ) can be achieved by adjusting the types and proportions of components in SEBS and SBS compounding systems to suit various industries with different application requirements.

At present, our company can provide general injection molding grade, extrusion grade, coating and bonding grade (which can be bonded to ABS, PA, PC, PP and metal), foaming grade, high resilience TPR product grades of various functional grades such as TPR grade, silicone touch grade, conductive grade, antistatic grade, flame retardant grade, laser engraving grade. Our company has strong R&D and innovation capabilities for TPR products, and can provide users with customized elastomer TPR product application solutions.

※Processing introduction:

Shaping method:

Extrusion processing: such as sealing strips, special-shaped strips, wire and cable jackets, etc.; span>

Injection molding: use a screw extruder (including general injection molding and overmolding); equipment For general injection molding machine \ two-color injection molding machine and so on.

Other molding methods: blow molding, drool calendering.

about the shrinkage rate of TPR - 1.5~2%.

※Material storage:

TPR pellets should be placed in a cool and dry place;

Opened materials should be packed in a timely manner after being taken out, and kept away from moisture and impurities and dust pollution; span>

For TPR materials that have been placed for a long time (more than 1 month), it is recommended to bake them and then process them.